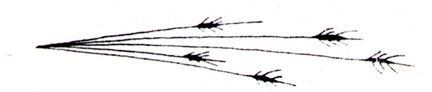

long yellow streaks, becoming leaf like in shape before expiring

Spark Testing is used to identify different types of steel.

Carvers are always unearthing tools at flea markets or reviving

tools passed down through generations. Sometimes it is just a

tool that has been over sharpened and it was your favorite. Whatever

the case, these are tools that you would like to be able to rework.

In order to do that you must know the steel. This is the only

way to know how to properly work the steel. Deferent alloys will

require different heats and methods for heat treating and using

the wrong ones will only make the matter worse. We are constantly

being asked to heat treat existing tools and unfortunately this

is not as easy as it once was. Spark testing used to be an easy,

quick and accurate way to determine the type of steel. Then you

could proceed with proper heat treating. In today's world of steels

there are virtually thousands of different alloy combinations

used in industry and this makes spark testing all the more difficult.

Even the manufacturer will change the type of steel from batch

to batch. This makes it virtually impossible to properly identify

the type of steel. Therefore, spark testing is not used as it

once was, but it can be used to get a rough classification.

Sparks will fly off steel when put to a grinding wheel and each

kind of steel produces a different color and volume of sparks.

The volume of sparks depends on the carbon content. Wrought iron,

which has very low carbon produces very few sparks. High carbon

produces many sparks. Here are a few examples of what to look

for when spark testing.

Spark testing requires some practice to correctly classify

the steel. The pressure used in grinding all the pieces should

be the same. The lighting should always be the same. This is not

unlike heat treating when you are learning the colors. It is a

technique that its better to be shown than to read about, for

once you see the colors it easier to work from there. Keep in

mind the lighting for one shop will be different from another

and this can produce entirely different colors.

Now this may help you determine if the tool is worth pursuing.

You will find that of the thousands of alloy steels available,

only a few are really of interest to wood workers. We use a very

simple steel that has very little alloy content and this is because

we are looking for the longest lasting edge. Our steel has only

a trace amount of vanadium for this aids in the forging process

and provides the steel with a finer grain. This is very desirable

for our tools. Most woodcarving tools will be a high carbon steel.

When we are asked to rework other tools we look at them on a piece

by piece bases. It is easier to work with older pieces, as the

alloys are more predictable. More often than not it is not worth

the extra time and money involved to reheat treat existing tools

unless you are sure of what you have.