The Cutting Edge

Interesting Tidbits for the Sharp Minded

|

|

|

The Cutting Edge Interesting Tidbits for the Sharp Minded |

|

Cape Forge 31 Berkshire Way Simsbury, Ct 06070

1-888-310-EDGE (3343) www.capeforge.com |

||||||||

|

||||||||

|

Quick Links |

||||||||

|

Featured Link |

||||||||

|

In honor of the upcoming Ward show, I thought you might enjoy a few

excellent bird museums. Bird carving is such an amazing art and if you get a

chance to visit a museum or woodcarving show, you will be instantly struck

by the level of detail that goes into each piece. I am always in awe.

Southwest Harbor ME Huntington, VT Salisbury, MD

|

||||||||

February 2012

Whatís New.....

When January comes around you feel like you have so much time, suddenly February is almost over and all the extra projects are still just ideas waiting to happen. Not sure if it is an age thing, or if time just really does get faster. I guess if I was looking to pass the blame, it would have to be on the weather this year. We had such a crazy Fall, weather- wise. Beginning with hurricane Irene in August, which halted our travels to the Down East Show in Maine, followed by a freak October snow storm that left our entire town without power for 9 days. Which meant no internet, no phone, and yes, no work. (See the photos below.) Now here we are in February and it feels like spring. The birds are chirping and I barely need to turn on the heat in the shop. Very interesting year. As for business, dad and I are restructuring a little to open up a bit more of his time so he can have the illusion of retirement. I will be spending more time in dad's shop working with him. This actually makes it more fun, although I don't know that we have been more productive yet. You may have also noticed that this has slowed down the production of chisels. As dad gets older, I don't see him speeding this up any, so plan accordingly. All the other tools are the same. It is also the time of year we start trying to get a bit ahead for the Ward Show and with the way time is flying the show will be here before we know it.

..

..

The photo on the left is my backyard and you can see it was quite close to the shop. The photo on the right is a typical street in town. It really did seem unreal. We are still cleaning up trees and have a renewed appreciation for power.

Interesting Tidbit.... I am the age that Dad was when we started the business. I thought about giving you the specifics, but where would the fun in that be. I will say that I am still pretty young in woodcarving years....

Now a Little SHOP TALK

Turning specs into tools...

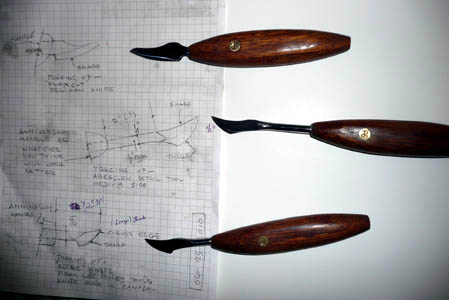

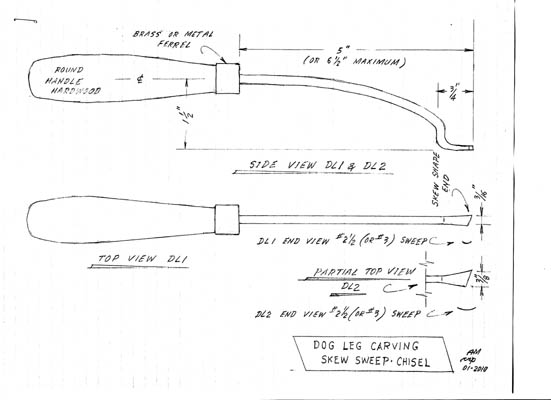

On average we make one or two custom tools a month and this can mean anything from just a bit shorter, longer, bend it, match existing tools on the market, custom handles, and ideas that are designed for a special need. Some take longer than others, for example I am working on a purfling pick right now that is quite a bear to get the right bend. I have made it twice already and will be doing another shortly. I will sometimes just make two because I think it is an interesting idea and we can bring the extra to shows. It is fun at the shows seeing carvers light up when they picture where the tools will work in their project. This is why I can say without reservation that no two carvers are alike and don't think that any one tool is the only way to make that cut. I really should photograph them all, but sadly I don't always find the time. What I thought might interest you, is how your ideas get transformed into tools.

Some folks send along the most specific specs and while this leaves very little question on what they are looking for, it sometimes does not match our methods. For example, we start by forging our tools from round stock and to take a tool that has been ground from flat stock, we have to alter the final look. We always try to keep the cutting results the same, but the tool can sometimes take on an entirely different look. I have also found that if you are looking for a tool within a 1000th of an inch, our hand made methods are not for you. We have made thousands of knives and I don't think any two are exactly alike. Then again some people describe what they're thinking over the phone and I make notes and a tool is born. Other will send along an existing tool for us to match. So there are many ways to get the results and I thought I would share a few ideas that might help you when dreaming of a tool and help us to create the tool.

t

t

We even match other handles as shown above.

The dimensions we need most are the length & width of the cutting edge. We usually require you to send along something specific for bends, for we have found that someone's gradual bend is not the same as the next. Shaft length is important if it needs to protrude from the handle. The thickness of the blades will usually be determined by the the length and use. We will sometimes drop the temper if you are looking for a very thin flexible blade for there are a series of compromise for relative hardness. So if you have dreamed up a tool that just might make your project easier you can always ask. I will tell you straight up if it wont work, or if I don't think it will do what you describe. Sometimes these ideas really do work We always give estimates for these tools, but here are a few basics for price.

Add a bend $8-$12

for knife lengths over 1 3/4" -Add $6.00 for every 1/2"

Custom handles Add $0 - $10

If you haven't already, become a fan and you won't miss a thing

Like us and become a fan on Facebook

Upcoming Shows....

The 42nd Ward World Championship Wildfowl Carving Competition and Art Festival

April 27-29th 2012

Visit our website for a complete listing of the years shows.

Customer Comments

The best part of our job is knowing the tools are being enjoyed and used. We love to hear from everyone..

If you are not convinced and would like to view more testimonials visit our web-site. We really do love to hear from you. Good and Bad. We have been known to screw up from time to time and we rely on you to keep us at our best.

Thanks for all your support and let us know if we can be of any service to you.

Until then Happy Carving!

The Father and Daughter Team of

Mike and Karyn de Punte'

Cape

Forge

Mail to:

Karyn

Mike

|

|